Shin-etsu

Bachtera Ladju is the agent and distributor for Shin-Etsu Silicone Rubber in Indonesia as imported directly from Shin-Etsu Chemical Co.Ltd, Japan.

Shin-Etsu is a leading manufacturer of silicone products in Japan.

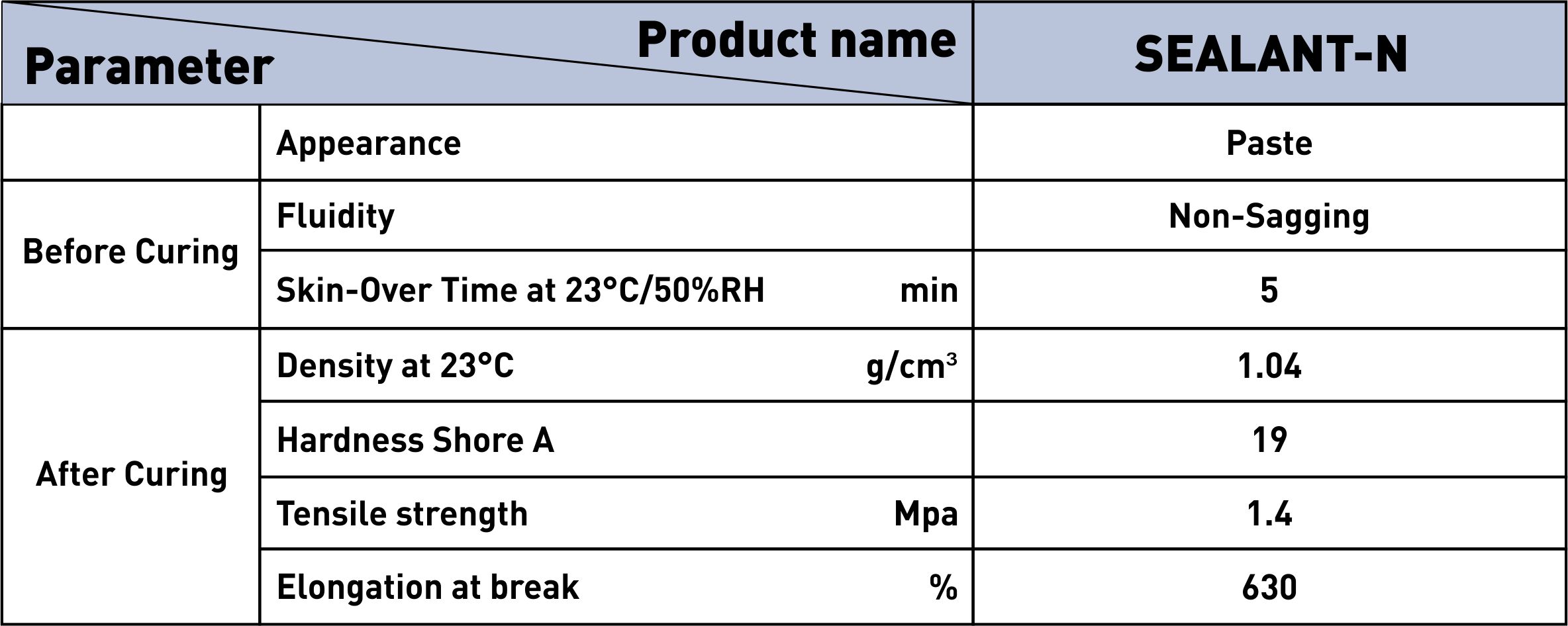

Bachtera Ladju is the agent and distributor for Shin-Etsu Silicone Sealant in Indonesia as imported directly from Shin-Etsu Silicons Ltd., Thailand.

Shin-Etsu is a leading manufacturer of silicone products in Japan and the nation’s largest manufacturer of silicone sealants.

Expertise: Silicone sealant and silicone rubber