ROBOT AUTOMATION SYSTEM - SPOT WELDING ROBOT AUTOMATION

The Motoman Spot Welding Advantage

As a world leader in robotic welding, Yaskawa Motoman offers spot welding robots with a broad range of payloads, reaches, integrated spot harnesses and servo-controlled spot guns. We have collaborated with automotive OEMs to create innovative robots to improve body shop productivity. Our SpotWorld platforms have helped manufacturers improve productivity and reduce time to market.

Increased Workspace Density

Floor space is a precious commodity. To help conserve that floor space and reduce overall machine footprint, we introduced a series of robots designed for higher robot density. The VS100 is a unique, low-profile 7-axis robot that can be positioned close to or under car bodies. The MS80W and MS165W are slim-profile robots that can be mounted close to traditional-sized ES165D/ES200D robots. These robots can be positioned closer to the workpiece and allow the product to be produced with fewer re-spot stations.

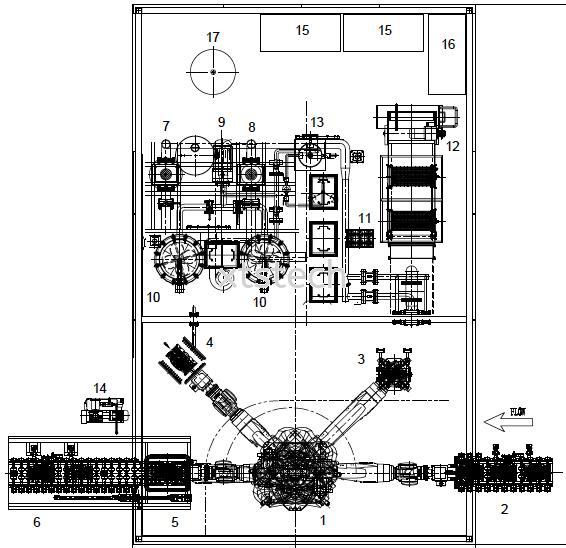

Product Changeover

Fast and predictable product changeovers are critical to maintaining throughput. NC locators, like the UH-series robots, allow rapid seamless line change. Programmed with X, Y, Z positions, the UH robots can move body mounting pins into new locations while a different body style is being transferred into station.

Workholding

We offer an extensive line of standard robotic positioners for work holding. Our low-profile 2-axis MotoPos and 3-motor MRM2 trunnion positioners are our most popular for SpotWorld workcells. Our patented MotoMount system makes installation easier, improves operation, reduces bearing stress and extends the life of the positioner. Fixture utility options to the faceplate make integration/changeover easy. All of our positioners can be customized to better fit the needs of your application.

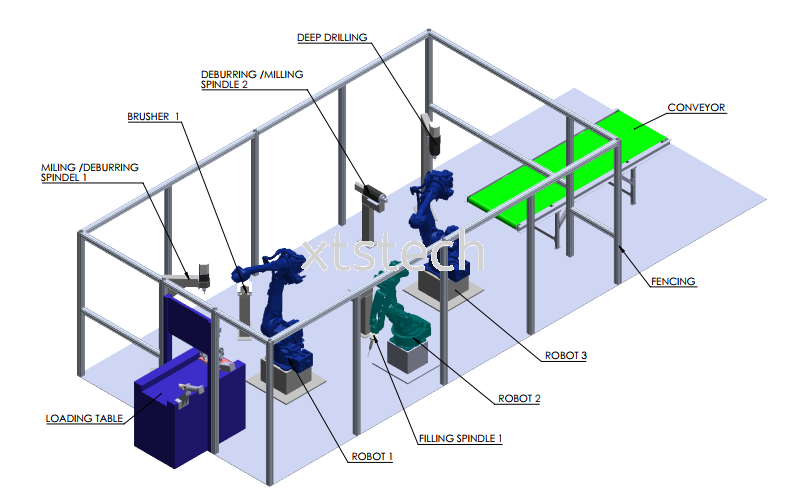

Coordinated Motion and Multiple Robot Control

We were the first robot company to develop coordinated motion of multiple robots from one controller. Coordinated motion enables multiple robots to work within the same space without the risk of one robot interfering with another. This feature allows our robots to manipulate larger parts for multiple process robots or work closely together without collisions. Coordinated motion also extends to external servo axes in our positioners, simplifying complex operations.

We continue to refine our software capabilities around coordinated motion maintaining our #1 position in the industry. Our systems are the easiest to program and deliver the best application flexibility. For example, by combining material handling robots with spot welding robots we can provide "jigless" processing, resulting in more flexibility and reduced tooling costs. Up to eight robots can be controlled from a single controller. Multiple robot control has been used to allow four robots on rails to pick up and transfer a car body between stations at a conveyor transition point.

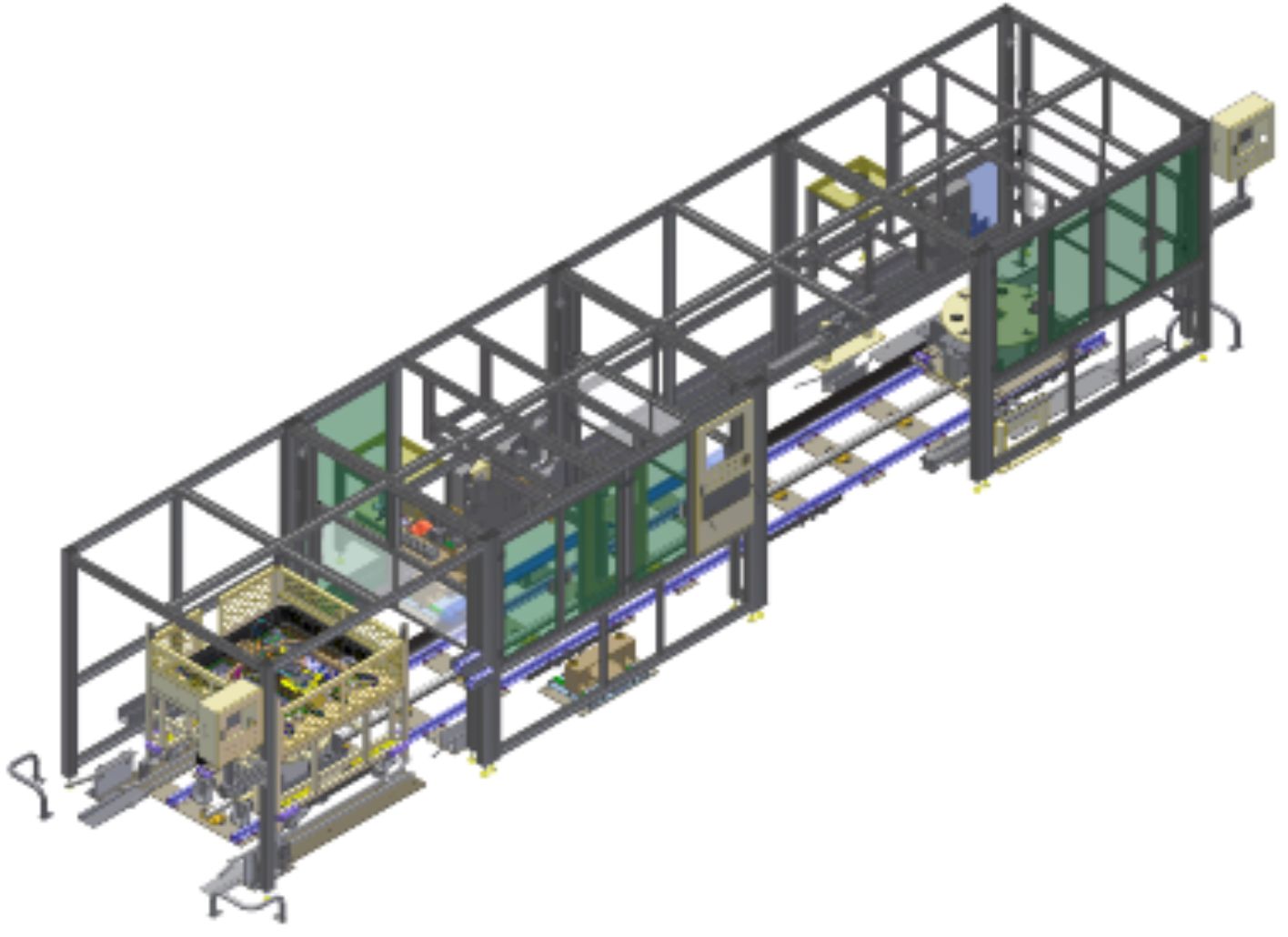

SpotWorlds

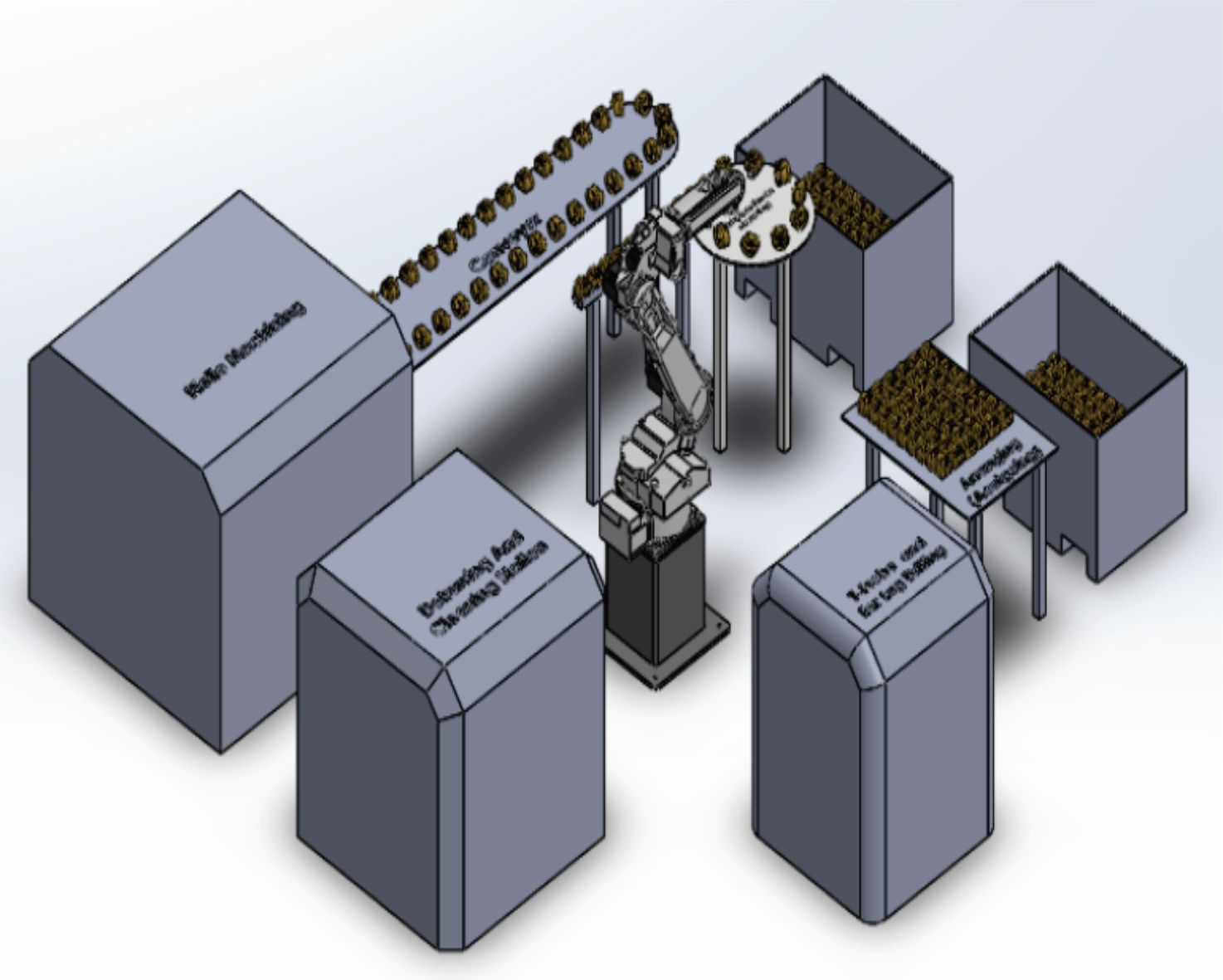

We revolutionized the robotic arc welding industry with a diverse offering of standardized pre-engineered workcells called ArcWorlds. ArcWorld cells can also combine a variety of workholding positioners, process equipment and safeguarding. These workcell configurations are easily adapted to spot welding applications as&nbp;SpotWorlds, which have been utilized in a wide range of industries, including automotive Tier suppliers, agriculture/construction equipment manufacturers and medical equipment manufacturers.

Customizations and Modifications

Projects often require modifications to our standard product offering of robots, positioners, platforms and peripherals. We offer an extensive array of customizations that ensure you get the system you need and start producing parts faster. Customizations and modifications include:

- Robot dress with guns and timers per OEM specification

- Modified positioners in a standard cell (or SpotWorld)

- Additional robots in a standard cell

- Additional positioning devices in a standard cell

- Material handling robots added to a standard cell

- HMIs or controls integrated into cell

- Custom cell (or SpotWorld) layouts

- Floor tracks added to a standard cell

Servo Guns

While we do not build the spot guns, we work with the leading manufacturers to make them lighter, more efficient and more versatile. We also ensure that the spot guns are integrated into our core controls and software, resulting in a more flexible, high-performance system.

A servo spot welding gun enables the robot to adjust electrode position based on motor torque feedback to provide the specified clamping force. Below are several benefits of servo guns:

- Minimizes electrode wear resulting in increased uptime

- Improves quality by providing consistent clamping force

- Eliminates ‘’squeeze time’’ wait for an air-gun to close resulting in reduced cycle time

- Servo-controlled guns are more energy-efficient than pneumatic guns driven with compressed air, resulting in real cost savings

Our software provides easy calibration for X or C type guns and supports offsets for gun arm deflection and tip wear compensation. Stepped pressure files allow the gun pressure to be varied during the welding cycle or during a tip dress cycle.

The spot welding harness supports motor and encoder cables for Yaskawa Sigma-5 servo motors, which can be integrated with the gun manufacturers drives. Control kits are available for Obara lightweight motors, Tolomatic ServoWeld actuators and Exlar actuators.

Integrated Spot Gun Harness

The integrated spot harness greatly improves throughput by eliminating downtime due to robot harness issues. Product launch times were reduced because simulation models and offline programs could be used ‘’as is’’ versus editing programs to avoid cable interference.

More Efficient Spot Guns

By using mid-frequency inverters for DC welding, transformer sizes have been greatly reduced. We have also worked with gun manufacturers to utilize higher frequency inverter switching (1,800-2,000 Hz) to help reduce gun size and weight, resulting in a more efficient and smaller system.

Weld Timer Integration

A single software instruction is used to initiate a spot welding cycle, including multiple spots in a row. A digital interface for Medar’s MedWeld 6000 MFDC weld timer allows weld schedules to be programmed from the robot programming pendant. The digital interface also provides the ability to program and monitor information from the MedWeld 6000 timer. Up to 255 weld programs are supported for each timer, and up to four timers can be networked with a multiple robot controller.

Ultrasonic welding by robotic arm we also able to design and manufacturing the system.